(iTers News) - Cathode and anode electrodes are key building blocks of a secondary battery cell.

To form the electrodes, manufacturers have to keep stacking alumina, or coppers layer after layer until the electrode are formed using a die and molding tool.

Futaba Corp. of Japan showcased an array of ultra-high precision die and molding tools at Korea EV trade show held from Oct 17 to 19.

The Japanese die and molding tool maker has established a joint-venture company with Kishin Corp. of Korea to supply Korea’s booming secondary battery market.

Kim Jae Jin, director & professional engineer with Kishin Corp. gives a brief demo on how to form a battery cell’s electrodes using Futaba’s die and molding tools.

He said that Futaba is now in talks with Korea's largest secondary battery cell makers to supply its die and molding system.

Let's bear with him as he introduces Futabas expertise in microscopic die and molding system.

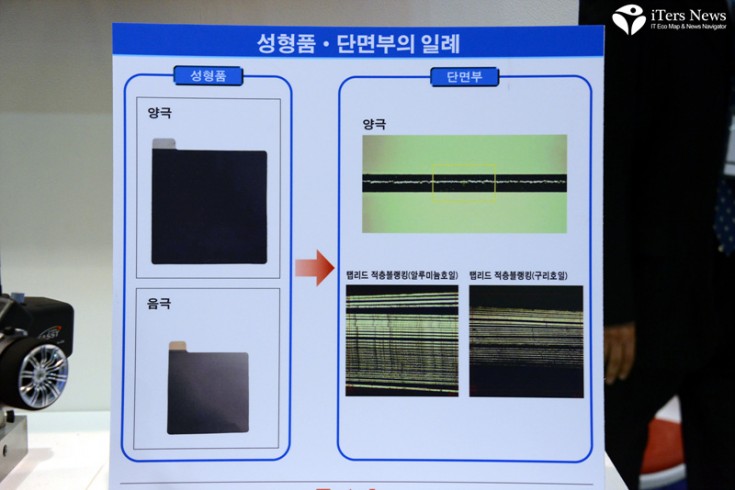

As you see, the electrodes of a rechargeable secondary battery are made of cathode and anode.

To create patterns of the anode and cathode, you need to have a die and molding system.

Futaba builds this micron-level special die and molding tool with our knowhow and expertise in ultra-high precision metal processing technology, which is instrumental in forming electrodes

The tool on the left side is a notching mold, while that on the right side is a compound-type die and molding system.

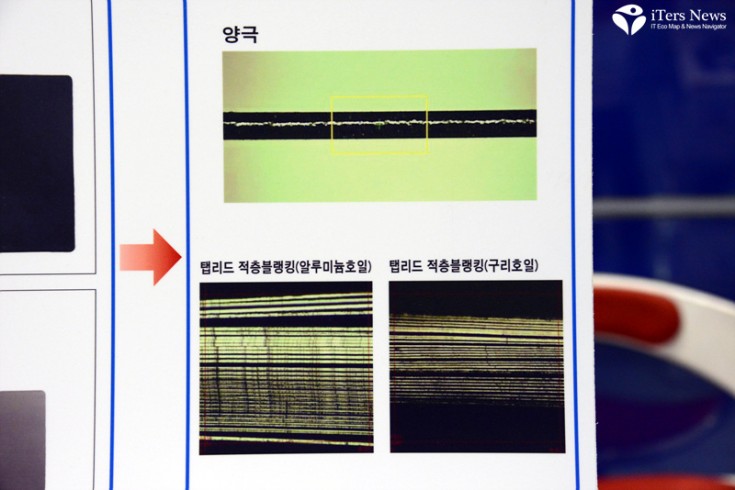

By using this molding tool, we formed this type of profile. If this aluminum- or copper-formed processing layer is not microscopically clean and precise, there should be defects. As Futaba’s die and molding system takes advantage of a microscopic ultra high-precision molding technology, however, there should be no defect.

So, if you stack continuously materials layer after layer, you can form this ultra-clean sliced profile

Manufacturers keep stacking this slice layer over layer until electrolyte fills in to the full, and then, they seal it with lumilite to form electrodes.

As Korea’s Li-ion secondary battery market is now booming, we plan to supply this molding system, allowing Korean battery makers to take advantage of our cutting-edge technology.

We have a great pride in our technology. Exploiting Futaba’s technology, a Korean joint-venture partner Kishin Corp. plans to manufacture this ultra-high precision molding machinery to supply them for Korean Li-ion battery makers."

Videos and Photos by JH BAE