(iTers News) - While electricity-powered passenger cars already hit roads, many industry experts sill bet that it will take for a long while before large-scale EV, or electric vehicle buses become commercially viable. Much of the blame for the commercial unavailability goes to the absence of long-lasting and efficient enough secondary rechargeable batteries to keep the electric motor, an engine of the EV bus, humming for until it is recharged again.

Immaturity of a dynamic wireless charging technology, which can consistently charge the EV bus on the run, is blamed, too.

Well known for its test-bed role in experimenting with the commerciality of a breakthrough technology, Korea proves it commercially viable.

Dongwon OLEV Co., Ltd. and KAIST, or Korea Advanced Institute of Science and Technology have successfully commercialized a whole set of the dynamic online wireless charging EV bus technologies from EV buses to an online wireless charging system.

Dongwon OLEV is a joint-venture between Dongwon Group of Korea, a food processing and deep sea fishery company, and KAIST.

Dubbed as OLEV, or online electric vehicle, the wireless charging EV bus system is now in the test-run operation in Gumi City, home to Korea’s mobile and display manufacturing cluster Gumi Industrial Complex, shuttling back and forth a 24km-long road lane. Under the lane is a long length of electricity –feeding power line system to feed electricity into 4 dynamic wireless charging stations under the road.

Commercial operation is scheduled to start sometime in 2014.

World’s first on-the-go wireless charging EV

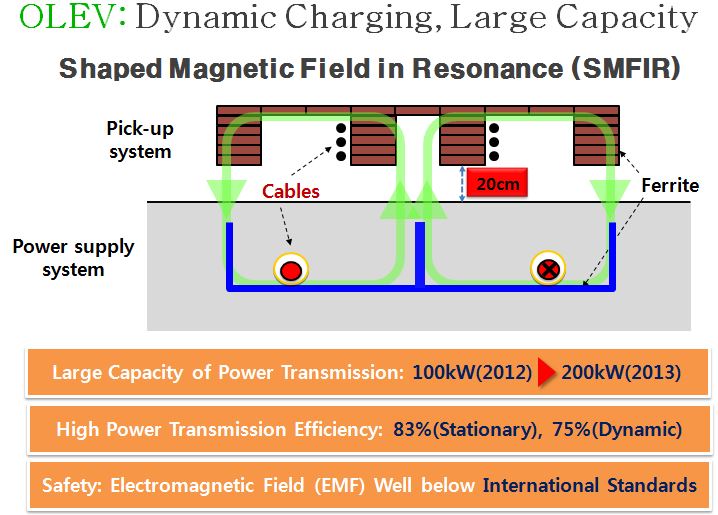

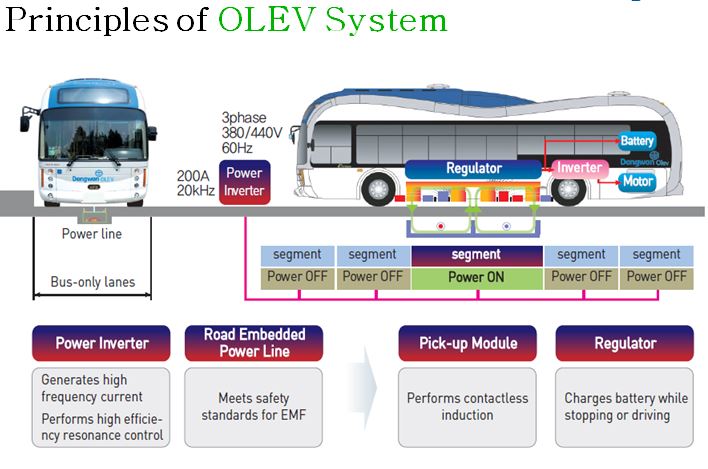

The power lines, which are buried under the ground, are to receive electricity from a power plant and then feed it through a dynamic wireless charging station into a wireless pick-up module system using what’s called as shaped magnetic field in resonance, or SMFIR.

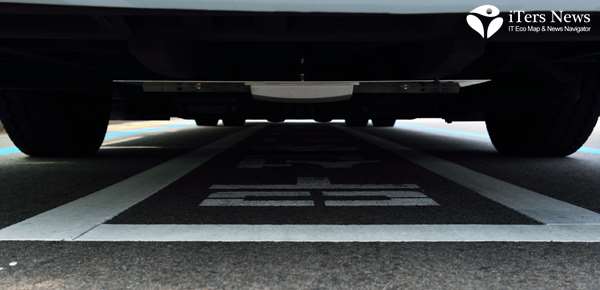

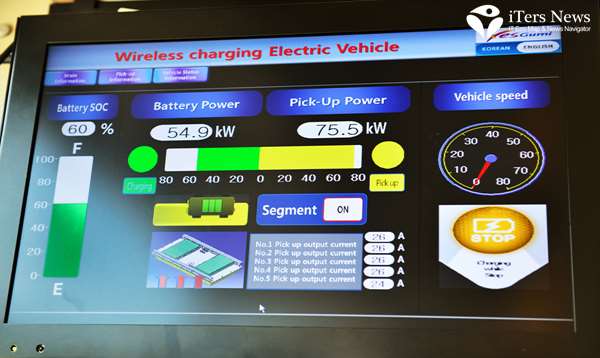

The working theory is straightforward. The power line supplies power, creating magnetic fields whenever the OLEV bus passes through the wireless charging docking system buried underneath the ground using the SMFIR. A built-in power pick-up module mounted on the underside of the OLEV bus then converts the magnetic resonance field into electricity to charge its built-in secondary battery. The battery powers up a built-in electric motor, an engine of the bus. As a result, the OLEV bus can receive 20kHza and 100 kW electricity, equivalent to 136 horsepower, at an 85% maximum power transmission efficiency rate, while maintaining a 20cm air gap between its underside and the road surface.

Once charged, the OLEV bus can run 58 km at the maximum, but, as its can get continuously recharged with no stop on-the-go, its actual driving range is unlimited. On the other hands, other rival stationary type of battery-powered EV cars hit limits in their one-time driving range. For example, GM-Lacetti EV car can only run just as long as 160km at best until it is charged again.

Key to this system is the SMFIR technology that enables the EV bus to keep charging its secondary battery engine on the run. By creating a large amount of shaped magnetic resonance field, the SMFIR technology can generate an electricity of up to 60 KHz and 180 kW of power to wirelessly charge up a built-in secondary battery.

At a press conference held in Gumi City on August 13, Chung Tae Sung, president with OLEV Co., Ltd. Said, “Our OLEV bus is the world’s first commercial roll-out of a dynamic wireless charging EV bus, while others are still struggling with stationary, or on-the-stop wireless charging system. The dynamic on-the-move wireless charging system enables us to tackle all tough technological challenges in commercializing EV bus.”

True enough, the OLEV bus system has cleared steer of the driving range limits, as it can keep charging its battery system. It also helped reduce the weight and costs of the EV bus, because it doesn’t need big, bulky enough rechargeable secondary battery systems to get the engine up and running for long miles.

For example, its built-in rechargeable battery is one third the size of the conventional secondary battery system that powers other electric vehicle buses of the same size. Safety feature is outstanding, too, satisfying an international EMF, or electromagnetic field standards of 62.5 mG, Its EMF is measured at 51.5mG, far below the standard.

Fuel-economy is also higher than other diesel, or CNG-fueled buses. For example, the OLEV can cruise half a kilometer per kilo watt, or costing just less 20 cents per kilometer. On the other hand, the diesel and CNG buses drive 2.7 and 1.7 kilometers per liter, respectively, costing almost double than the OLEV.

Its infrastructure equipment and installment costs are economical, too, because it doesn’t need to build up the power supply lines along all the way through the EV bus lane. For example, it just takes a 144 meter long power supply line to build a 24km-lenhth EV bus lane. The EV bus lane can be also be commonly used by other conventional buses, because its proprietary ‘segment’ technology can intelligently control the power supply lines by switching on the power strip when OLEV bus passes along, but turning off the power grid for other conventional vehicles, preventing EMF exposures and standby power losses.

Applications are diverse fr om public tranist systems like buses and trams to passenger cars. The technology can also be used for industrial vehicles, various cranes for sea port container terminals as well as railway sysetm Yet, the OLEV bus is still an expensive luxury, as it cost almost 700 million won per unit o build. To cut back production costs, the company needs to establish economies of scale. According to Dongwon OLEV, once it builds an annual production capacity of 270 to 300 units, it can reach a break-even point. And then, the company will have a room for lowering the costs to somewhere near 300 million won.

Yet, it will take for a lone while before it reaches a big enough critical mass to make the EV buses affordable green-energy car. For example, Gumi City got a financial subsidy of 4.8 billion won from the central government to build the whole online wireless charging transportation system, including two OLEV buses, 4 dynamic charging stations, 2 stationary charging docking systems, and 144 meter-long power supply lines.

That’s the price that we have to pay to live a carbon dioxide gas-free clean and green ecology.

Videos & Photos by J.H. Bae